Current Position:Jilin Mekoo Pipe systems co;LTD.>News>New>The role of oxygen barrier pipeline in floor heating

Release Time:2020-08-18 14:51:21 Views:times

In recent years, with the passage of time, floor heating has been recognized by more and more people. Domestic floor heating products have many advantages in manufacturing technology, cost control, and market share. So, why use oxygen barrier pipes for radiant heating on the ground? Today we will introduce to you.

In the heating system, the oxygen in the water will seriously corrode the metal surface for heat exchange and reduce the life of the system. The boilers and radiators in the heating system will be the main corrosion targets. Since the oxygen content in the water is related to the water temperature, the higher the temperature, the lower the oxygen content, and the lower the temperature, the higher the oxygen content-that is, the oxygen dissolved in the water will be absorbed or separated due to temperature changes, so the oxygen will pass through the pipe The surface enters the water in the pipeline and is released in high-temperature heat exchange surfaces such as household boilers, water separators and heat sinks, and chemically reacts with metals, causing corrosion.

Especially in the floor heating system, the pipe heat exchange area is large, and the oxygen permeability is more serious. However, the permeability of the general floor heating polyethylene pipe is 0.1mg/liter/day, which meets the German Industrial Standard DIN4276 standard. Therefore, the oxygen barrier layer of the floor heating pipe is of little significance to oxygen barrier, but this oxygen barrier protective coating can greatly Improve the anti-friction ability of the floor heating pipeline and increase the life of the pipeline. For owners who pursue high-quality, they should consider choosing.

In Europe, steel plate radiators are the most commonly used hot water heat dissipation equipment, so heating pipes must block oxygen, and PB pipes must also have an oxygen barrier layer because of its extremely high oxygen permeability. PB pipelines use less than 8% of floor heating in Europe and have disappeared in the United States, which is determined by the characteristics of the pipeline itself.

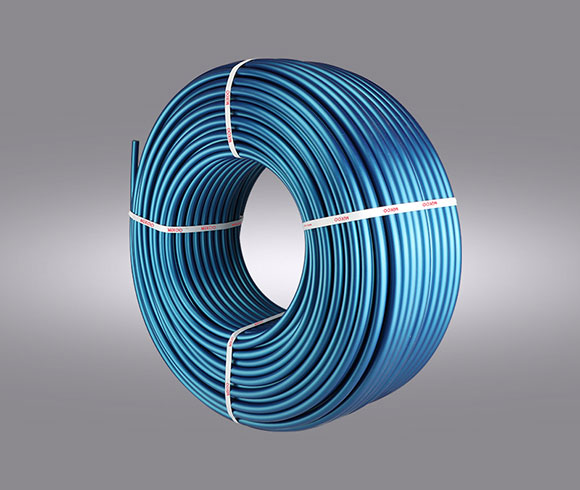

Oxygen barrier pipe products are formed in two structures: three-layer co-extrusion and five-layer co-extrusion. Five-layer co-extrusion oxygen-barrier pipe has a better oxygen barrier effect and more reliable than three-layer co-extrusion pipe. Five-layer co-extrusion resistance The oxygen tube has only the outermost layer of plastic connection at the connection between the pipe and the fitting, which ensures the safety of the connection.

The electron beam radiation cross-linked polyethylene (PE-Xc) tube uses high-energy rays to excite polyethylene molecules to generate free radicals, which combine to generate intermolecular cross-linked bonds, forming a cross-linked structure of polyethylene molecules.

Modification of HDPE by physical method, the formation of cross-linked polyethylene and three-dimensional network structure.In the electron beam irradiation source intensity under certain circumstances, for a certain limit complete modification.

High oxygen barrier type PE-Xc pipe through multi-layer coextrusion technology, the formation of EVOH oxygen barrier layer is uniform in the external pipe.

Meigao PE-Xc tube adopts the first domestic co-extrusion irradiation technology to co-extrude the visible light barrier layer and the ultraviolet absorption layer into the tube.1、It can prevent sunlight transmission from oxidizing the water quality, and then avoid the production of bacteria and algae growth that will seriously affect water quality, pipeline transportation and other problems;2、It can prevent the pipes from being exposed to ultraviolet rays in the atmosphere to cause aging, so as to further i

Jilin Meigao Piping System Co., Ltd. originated from the Changchun Institute of Applied Chemistry, Chinese Academy of Sciences. It is a high-tech enterprise integrating R&D, production and sales of pipeline products and accessories. The company mainly produces electron beam irradiation cross-linked PE-Xc Pipes, heat-resistant polyethylene PE-RT pipes, PP-R pipes, pipe fittings, complete specifications.