Current Position:Jilin Mekoo Pipe systems co;LTD.>News>New>Tips: performance comparison of various floor heating pipes

Release Time:2020-08-18 14:58:35 Views:times

At present, the floor heating pipes supplied on the market are mainly made of PE-RT, PE-Xa, PE-Xb, PE-Xc and other pipes. Faced with so many pipes, what choice should the user make? Let's analyze the main characteristics of these pipes one by one, so as to select the pipes correctly and reasonably.

1. Heat-resistant polyethylene (PE-RT, the molecular structure is a linear one-dimensional structure). The application of PE-RT pipe started late, because it does not require special equipment (50,000 to 100,000 yuan per production line) and the process is particularly simple. Production There are many and miscellaneous companies, and some companies use HDPE materials to pretend to be PE-RT, etc. Also because the materials themselves are not resistant to high temperature, high pressure and other factors, quality problems often occur. So far there is no national standard, only the industry standard CJ/T175 -2002. Its density is only 0.925 g/cm3 (as can be seen from the transparency of the pipe), the structure of the molecules is sparsely arranged, the crystallinity is low, the resistance to oxygen permeability is poor, and the material body is very susceptible to aging by oxygen. It is rarely used in European countries.

2. Peroxide cross-linking (PE-Xa, the molecular structure is a planar network). The PE-Xa pipe is difficult to control due to its complex process and various product properties due to environmental, equipment, and human factors.

3: Silane crosslinking (PE-Xb, molecular structure is three-dimensional network). Due to environmental protection and other reasons, only a few domestic companies produce PE-Xb pipes. Due to the pollution of drinking water to the pipe, the European Communist system has banned its use in food contact occasions. The use of PE-Xb pipes was banned in Europe in 2004.

4: Irradiation crosslinking (PE-Xc, the molecular structure is a three-dimensional network). The PE-Xc pipe is cross-linked by radiation (belonging to the physical cross-linking method). This pipe has performances such as pressure resistance, temperature resistance, cross-linking uniformity, product stability, chemical resistance, environmental stress resistance, and service life. And has a strong advantage in environmental protection. It has been recognized by more and more peers and experts.

The matrix material of the irradiation cross-linked polyethylene pipe is high-density (density ≥0.94 g/cm3) polyethylene, with closely arranged molecular structure, high crystallinity, and strong resistance to oxygen permeability. Meigao PE-Xc pipe has been tested by National Chemical Building Materials Departmental testing, product performance meets national (GB/T18992.2-2003) and German standards (DIN16892). Passed the National Ministry of Health's product testing (GB5749-2006) related to drinking water hygiene and safety, and meets drinking water standards. Irradiation cross-linked polyethylene PE-Xc pipes have proven to be reliable after more than 40 years of application in Europe.

Summary: Because the low-temperature floor radiant heating project is a concealed project, and 60 degrees Celsius hot water is passed in the system, this means that when the local heating pipe bursts due to quality problems, the ground of the building will be destroyed. The loss is huge. Therefore, floor heating pipes used in low-temperature floor radiant heating systems have higher requirements than plastic pipes used in ordinary buildings: the system must strictly select the material, type, manufacturing process and quality of floor heating pipes. Only in this way can the 50-year life span of the low-temperature radiant floor heating system be realized.

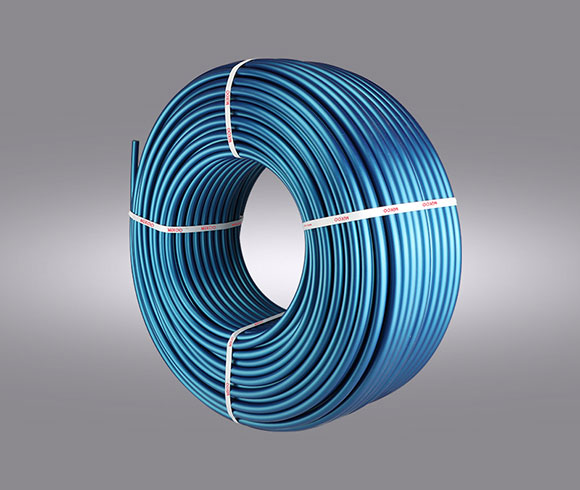

Meigao electron beam irradiation cross-linked polyethylene (PE-Xc) tube, you deserve it!

The electron beam radiation cross-linked polyethylene (PE-Xc) tube uses high-energy rays to excite polyethylene molecules to generate free radicals, which combine to generate intermolecular cross-linked bonds, forming a cross-linked structure of polyethylene molecules.

Modification of HDPE by physical method, the formation of cross-linked polyethylene and three-dimensional network structure.In the electron beam irradiation source intensity under certain circumstances, for a certain limit complete modification.

High oxygen barrier type PE-Xc pipe through multi-layer coextrusion technology, the formation of EVOH oxygen barrier layer is uniform in the external pipe.

Meigao PE-Xc tube adopts the first domestic co-extrusion irradiation technology to co-extrude the visible light barrier layer and the ultraviolet absorption layer into the tube.1、It can prevent sunlight transmission from oxidizing the water quality, and then avoid the production of bacteria and algae growth that will seriously affect water quality, pipeline transportation and other problems;2、It can prevent the pipes from being exposed to ultraviolet rays in the atmosphere to cause aging, so as to further i

Jilin Meigao Piping System Co., Ltd. originated from the Changchun Institute of Applied Chemistry, Chinese Academy of Sciences. It is a high-tech enterprise integrating R&D, production and sales of pipeline products and accessories. The company mainly produces electron beam irradiation cross-linked PE-Xc Pipes, heat-resistant polyethylene PE-RT pipes, PP-R pipes, pipe fittings, complete specifications.